Ensuring that plastic buckles are produced to a high standard and meet today’s specifications for sustainability and performance can be a challenge for manufacturers. Nifco’s careful quality control measures ensure that the finished product achieves the standards of excellence and quality that our customers deserve.

Table of Contents

Excellence in plastic buckle manufacturing requires effort

Nifco’s best fit for people and planet is a demanding principle for modern plastic buckle manufacturing. There is a constant need to develop and refine products to respond to customer and consumer requirements for fashionable, lightweight, reliable and sustainable buckles and fasteners.

What are Nifco’s 5 areas of excellence in quality plastic buckle manufacturing?

- Plastic buckle & fastener design, research and development

- Prototyping and refinement of customer designs and new concepts

- Quality Control to ensure consistency of structure & finish

- Product Testing for dependable, reliable customer service

- Sustainability of materials, manufacturing & supply chain

We have achieved and maintained our leadership in plastic buckle manufacturing by strict attention to the whole lifecycle of our products. Our integrated in-house customer service, design and manufacturing ensures that our buckles and fasteners exceed all expectations.

Plastic buckle & fastener design, research & development

Nifco has an active research & development team constantly looking for ways to improve our designs and manufacturing processes. Recent major innovations include significant gains in weight reduction without compromising on strength as well as confirming the viability of manufacturing standard designs in recycled plastics.

Prototyping & refinement of customer designs & new concepts

When our customers come to us with a new design or concept that they want to create for their brand, we are always very eager to help them discover the best way to realize their inspiration as an effective, attractive, durable and sustainable product.

Crossover designs for consistently fashionable brand styling

We are skilled development partners in the creation of plastic buckles and fasteners that match your brand style without losing functionality and efficiency. We look outside conventional categories to manufacture products, like the Bungee Lock System FW25 PPT pictured above, that cross boundaries between shoe and apparel fasteners to generate new, fresher styles.

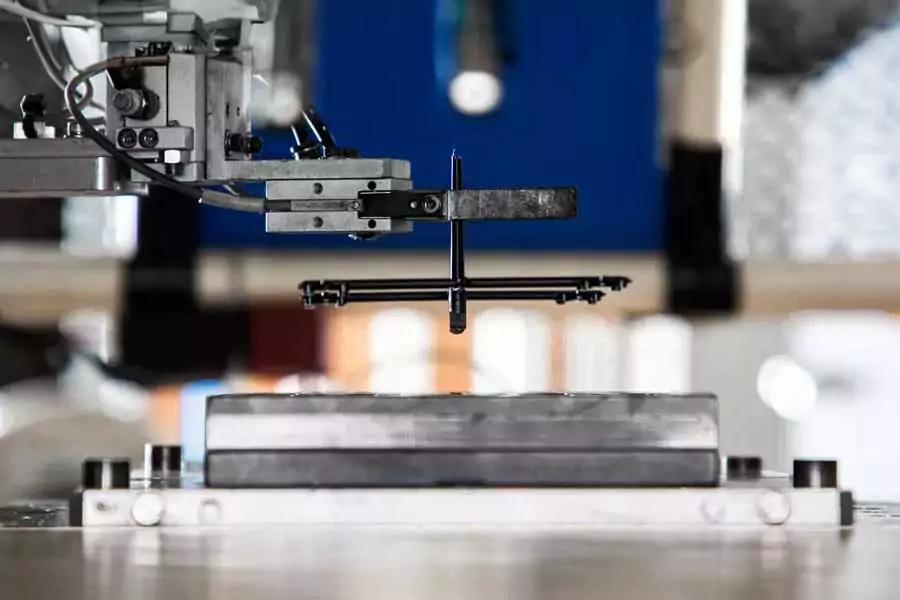

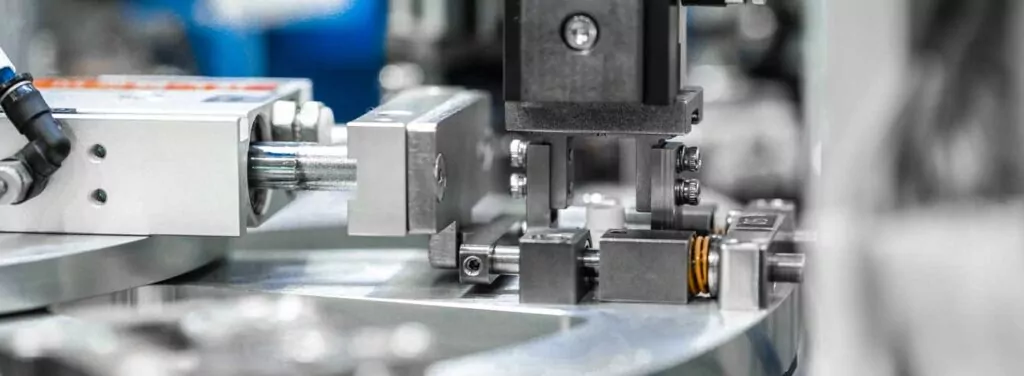

Quality control to ensure consistency of structure & finish

Nifco quality control is evident at every stage of the product life cycle, from supply chain material procurement through to ensuring designs will maximize end of life recycling. Our extensive experience with materials and molding technologies assist in ensuring that every Nifco product undergoes consistent manufacturing processes for perfect duplication of each design.

Product testing for dependable, reliable, customer service

Destructive testing ensures fasteners will function properly for the life of apparel and footwear, and flow tests verify the applicability of sustainable plastics to maintain the quality standards of our tried and tested favorites. For more than half a century we have been supplying our customers with dependable products manufactured to our exacting standards.

Sustainability of materials, manufacturing & supply chain

Contemporary consumers demand sustainable products, and Nifco supports the green credentials of our clients by manufacturing fasteners in recycled POM and Nylon PA6. Our ISPO Textrends award winning development of Nylon PA6 fasteners for use with clothing made of nylon fabrics increases the ease of post consumer recycling and promotes the circular economy.

The future of high quality plastic buckle manufacturing is Nifco

Contact us to discover the future of quality leadership in plastic buckle manufacturing, and discover our extensive catalog of thoughtfully designed and engineered products, built over half a century of innovation and customer service.