Current and emerging EU legislation is increasingly tightening on overseas manufacturing that fails to meet high environmental standards in the green economy.

Table of Contents

How is the EU responding to climate change?

The EU goal for climate neutrality is central to future environmental planning and legislation to reduce the impacts of climate change. In 2019, in the EU Green Deal, EU leaders passed the EU Clmate Law, which enshrines the objective of making the EU carbon neutral by 2050 into legislation. This followed on from the Paris climate agreement of 2015.

Now the stage is set for the development of a wide range of policy and legal requirements that will be implemented over the coming years. The EU is taking a comprehensive approach that mainstreams climate change across all sectors and areas of society. This means that eventually all products and services will be reviewed and checked.

The five features of EU climate neutrality

- Commitment to emit less and absorb more greenhouse gasses

- The Green Deal is new, but EU climate action has been a reality since 2008

- EU Climate Neutrality is not just about environmental policy, it covers all aspects of human life

- The EU is financially supporting inclusive implementation across all member states

- EU climate ambitions shape global action against climate change

Climate mainstreaming affects all EU policy areas and economic sectors

What is truly new about the EU’s climate-neutrality goal and the Green Deal is that they require action from all sectors of the economy and integrate climate and environmental considerations across all EU policy areas. This is known as climate mainstreaming.

Current legislation is focused on emissions, fuels and energy, and the importation of manufactured goods that have a significant carbon footprint. The new Carbon Border Adjustment Mechanism (CBAM) will charge importers who cannot prove imported goods have been manufactured to environmental standards that meet or exceed EU requirements.

At present CBAM is applied to larger items and engineering components, but it is likely that the legislation will expand to cover a wider range of imported manufactured goods and components over time. EU brands will not be able to hide unsustainable manufacturing and outsourcing by greenwashing.

The EU is committed to recycling and a circular-economy model

the way we produce goods must adapt to a circular-economy model where, for example, textiles, construction materials and electronics are recycled or re-used in order to decrease the use of primary raw materials

The EU climate-neutrality goal is also committed to increasing reuse and recycling. Similarly to historic environmental protection directives it can be expected that manufacturers who are able to supply confirmation that their products incorporate materials from reliable reuse and recycling will be exempted from cross border tariffs designed to fine manufacturers who are not focused on environmental protection in their production and manufacturing processes.

What is the EU fit for 55 plan?

The EU has an ongoing program to reach climate neutrality. The EU fit for 55 plan for a green transition already includes emerging legislation that applies to carbon-intensive goods imported from countries that do not have carbon pricing policies in place to fight climate change.

Companies in the EU are required to conform to carbon reduction legislation and this adds to production costs. The purpose of EU legislation to control carbon emissions and creation is to stop businesses from importing goods into the EU that are artificially competitive because they do not include the cost of environmental compliance.

The EU recognizes the need to increase the cost of imported goods from places that do not apply the same environmental standards to avoid ‘carbon leakage’ – where businesses relocate production or switch to importing carbon-intensive products to avoid EU costs of compliance.

Without legislation, the EU’s efforts to reduce greenhouse gas emissions would be made ineffective through imports of products manufactured in non-EU countries whose climate change policies are weaker than the EU Fit for 55 policies.

How might imports into the EU be affected by emerging legislation?

Current legislation affects some businesses importing goods into the EU from countries and businesses that do not have carbon offsetting systems or regulation. This is especially problematic for companies that outsource to emerging, high growth countries in Asia such as Vietnam, where there is no equivalent to EU climate legislation. Imports from these countries can be expected to attract high tariffs.

Can EU businesses reduce the risk of attracting climate change tariffs?.

The short answer is yes. The EU already has in place trading schemes and agreements for carbon offsetting. These respect the standards of trading partner countries that also require businesses to act to reduce emissions and improve their environmental footprint.

Another way of reducing the likelihood of climate change tariffs is to import from manufacturers who use recycled materials and renewable energy in their production process. Existing EU environmental protection schemes, including the WEEE directive for electronic waste, offer exemptions for reused and recycled goods.

Nifco green manufacturing supports future-proof businesses

Nifco Buckle has an excellent record of sustainable design and manufacturing that enables us to supply products to meet all conceivable future standards for environmentally friendly materials. This is why leading global brands see us as a dependable and sustainable partner of choice.

With Nifco you don’t have to worry about future legislation making our partnership uncompetitive. Our designs and systems meet international standards for sustainability, and our facilities are in countries that can meet EU regulations for environmental protection.

The best fit for people & planet

Our philosophy is to create the ‘best fit for people and planet’ with fasteners and buckles designed to meet human needs for ease of use, reliability, and style with innovative manufacturing that safeguards the environment.

To meet UN goals for plastics reuse and recycling, we have minimized the volume of plastic used in product design and manufacture. We also use readily recyclable plastics, eliminate production waste, and include post consumer recycled plastic when this is possible.

- ReNifco closed cycle production

- Plastics that are easily recycled

- Design optimization reduces the volume of plastics required

- Using recycled plastics in new products

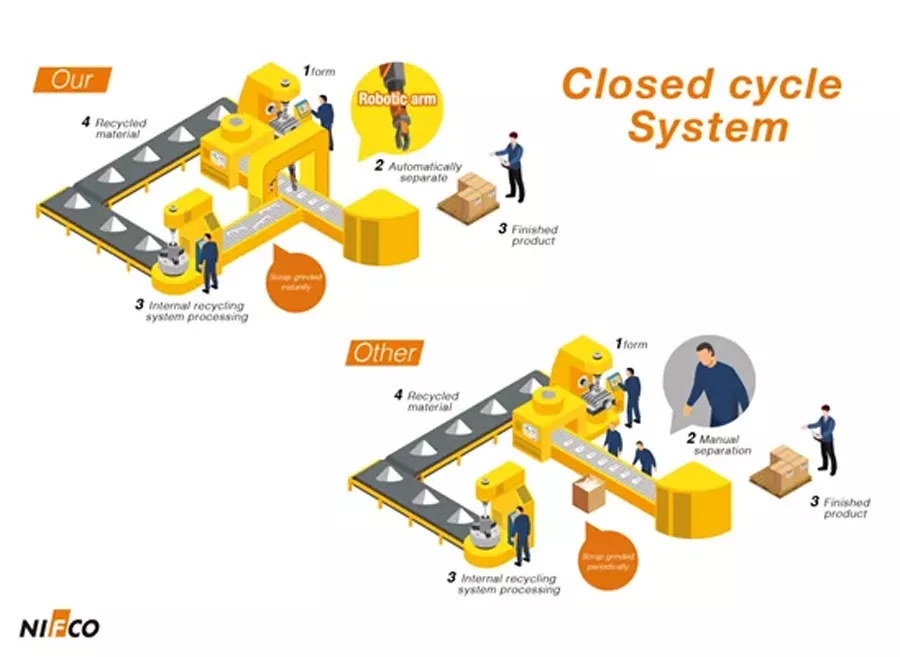

ReNifco closed cycle production system

ReNifco is our automated closed cycle system for reusing manufacturing waste from the molding of buckles and fasteners. Plastic and sprue trimmings are immediately reground, extruded, and sent back into the production feed.

By contrast, open cycle production uses more plastic to manufacture the same products, and waste is often sent off-site for reprocessing. For these reasons open cycle production is less efficient and has a larger carbon footprint than closed cycle production.

The four benefits of closed cycle production

- manufacturing waste is eliminated

- reduced environmental impact of transport

- No waste goes to landfill

- No need for on-site storage of waste products.

Plastics that are easily recycled

Our recycling commitment can be seen in how we use easily recoverable and recyclable plastics and include post consumer recycled plastics in new products where possible.

Design optimization reduces the volume of plastics required

Nifco has continuously innovated in material and design for decades to provide our customers with products like our SRGT range of side-release buckles, including the BBU25 for a sleek urban look. These meet the need for lighter, smaller, more reliable buckles and fasteners. Requiring less material to manufacture, delivering better performance, and offering customers ease of use and design appeal.

Using recycled plastics in new products

Our ultralight range includes recycled cord stoppers like the CSUA-15 pictured above. At weights much less than one gramme, these products are also game changers in minimizing material use.

Ask us about our best fit solutions for greener manufacturing

Our customers want the best fit possible between function, design,and appearance. Our long experience of innovation to satisfy their needs gives us a wide range of best practice solutions for environmental responsibility. Not only does green manufacturing help build customer confidence in brand sustainability, it also safeguards you against future legal requirements aimed at fighting climate change. Talk to us to find out how we can help you meet the emerging challenges arising from the need for environmental sustainability. Nifco specializes in offering future-proofed high performance buckles and fastening solutions that don’t compromise your needs for high performance buckles and fasteners for your products.