The impact of COP27 on plastic fastener manufacturers

Plastic fastener manufacturers are among the global businesses who will be affected by the outcomes of COP27, currently underway in Sharm el-Sheikh. Here we look into the background of COP27 and consider the implications for global business strategy.

Table of Contents

COP27 Climate Change Conference: November 2022

At COP 27, country leaders are meeting to decide what action to take to achieve the collective climate goals agreed in the Paris Agreement of 2015. Leaders are expected to open up a new phase of response to climate change by turning their commitments under the Paris Agreement into action.

The conference is taking place in Sharm el-Sheikh, Egypt, until 18th November. An important feature of COP27 was that heads of state were asked to submit their climate plans before the summit. Only 25 managed to do this, and it is not clear how leaders will commit to meeting climate change targets.

What does COP27 stand for?

- COP stands for Conference of the Parties. These are the countries that signed up to the original United Nations climate agreement in 1992.

- United Nations (UN) climate summits are held every year, for governments to agree steps to limit global temperature rises.

- COP27 is the 27th UN meeting on climate change. Meetings take place every year, and this year it is in Egypt, in Sharm el-Sheikh

- COP27 is being held in Africa, and is the fifth time a COP has been held in the continent expected to be the worst affected by climate change.

- Reducing emissions is a central aim of COP27, by reducing use of fossil fuels or switching to renewable energy.

What are the six main issues for COP27?

There are three key aims for COP27, in addition to three previous goals established in COP26 but not yet achieved. We can expect leaders to focus on these six issues:

- Reducing emissions

- Helping countries to prepare for and deal with climate change

- Securing technical support and funding for developing countries for the above

- Loss and damage finance for countries to recover from the effects of climate change

- Establishing a global carbon market that adds costs of emissions effects into global products and services

- Committing to reduce coal use

How are businesses responding to the threat of climate change?

The need to anticipate legislation, to take responsible action to reduce carbon footprints and meet corporate social responsibility targets has driven businesses to take action. There are two major initiatives that global businesses have adopted to future-proof against the economic impacts of climate change.

These initiatives are The UN Global Business Compact and Science Based Emissions Targets for Business – we should be watching to see how COP27 will meet the expectations of these two historic initiatives developed by businesses working towards UN goals as well as EU net zero 2050 targets.

UN Global Business Compact

In May 2020, 155 companies signed a joint statement to urge world governments to combine actions focused on COVID-19 recovery and economic aid with climate science goals. The signatories have a combined market capitalization of more than $2.4 trillion, and over 5 million employees.

As debates on recovery packages around the world ramp up, the companies, which are all part of the Science Based Targets initiative, call for policies that will build resilience against future shocks by supporting efforts to hold global temperature rise to within 1.5°C above pre-industrial levels, in line with reaching net-zero emissions well before 2050.

Science based emissions targets heighten corporate ambition

Science Based Targets for ambitious corporate climate action provide companies with ways to reduce emissions to meet the 2015 Paris Agreement goals. There are already more than 3,000 businesses that are working with this initiative to achieve concrete results that are good for business as well as the environment.

What are ‘science-based targets’?

Science-based targets are clearly-defined actions companies can take to reduce carbon emissions. The goal is to reduce the impacts of climate change and protect future business growth. The commitment of global companies to achieve these targets demonstrates the impact on business sustainability of failing to act now.

Targets are only considered ‘science-based’ if they meet the latest climate science that supports the Paris Agreement. This demonstrates the commitment of businesses to limiting global warming to well-below 2°C above 1850 levels and aiming to limit warming to 1.5°C.

What is the goal of COP27?

- UN climate scientists and the Intergovernmental Panel on Climate Change (IPCC) state that global temperatures have already risen by 1.1C above 1850s levels, and will rise to 1.5C.

- The IPCC warns that half the world population might be exposed to life-threatening heat and humidity if global warming reaches 1.7 to 1.8C

- In 2015, 194 countries signed the Paris Agreement, agreeing to attempt to limit global temperature rises to 1.5C.

- The goal of COP27 is for governments to agree ways to reduce global warming caused by human activities, mostly from burning fossil fuels like oil, gas and coal.

- Reduction in carbon emissions and establishment of a global carbon market are core aims of COP27

What can businesses do to help mitigate climate change impacts?

We might expect COP27 outcomes to influence UN Global Business Compact and Science Based Emissions Targets for Business initiatives, but the direction businesses are taking is clear. Global success depends on meeting not only the requirements of legislation but the demands of consumers to protect and preserve the environment.

Businesses are developing multiple competencies that contribute to mitigating climate change impacts. Many of these are sector and industry dependent, but the range of possible actions demonstrates that all businesses should be capable of taking action, and our customers are expecting to see evidence that we are working towards the same goals.

How can businesses reduce climate change impacts?

- Reduce carbon footprint and using renewable energy

- Use recycled raw materials

- Increase recyclability of products

- Manufacture reusable products

- Minimize material use in manufacturing

- Minimize manufacturing waste

- Make biodegradable products

- Manufacture greener product alternatives

Nifco: the plastic fastener manufacturer supporting climate change goals

Leading global brands choose us as a dependable and sustainable plastic fastener manufacturer because with us you don’t have to worry about being able to meet future legislation standards, or consumer demands for sustainability.

At Nifco Buckle we have a demonstrable track record of innovating to produce sustainable designs and applying waste reduction standards that enable us to meet or exceed emerging future targets for environmentally friendly plastic fastener manufacturing.

Nifco production systems and designs stay ahead of international standards for sustainability, and our customers can rest assured that our manufacturing facilities are in countries that can meet EU and global regulations for environmental protection.

The best fit for people & planet comes from Nifco

Our philosophy of ‘best fit for people and planet’ is clearly demonstrated by our innovative and sustainable designs for fasteners and buckles. Nifco designs match human needs for reliability, ease of use, and style while following best practice in safeguarding the environment.

Our minimal use of plastics and incorporation of easy to recycle plastics in our design and manufacture of products follows UN goals for plastics reuse and recycling. With the ReNifco manufacturing system, we eliminate production waste, and are able to incorporate post consumer recycled plastic into many product lines.

- ReNifco closed cycle manufacturing

- Plastics that are easily recycled

- Innovative designs reduce material use

- Ultralight products using recycled plastics

ReNifco closed cycle manufacturing

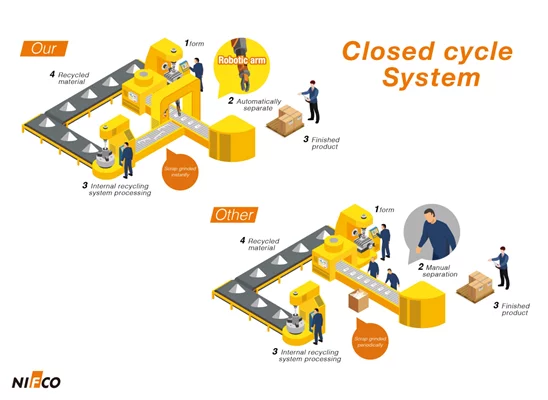

Nifco have developed an automated closed cycle in-line waste recycling system that reuses manufacturing waste from buckle and fastener moldings. Trimmings are reground, extruded, and immediately sent back into the production feed.

Compared to open cycle production, ReNifco uses less raw material and avoids the carbon footprint associated with sending waste off-site for processing. No waste goes to landfill, and there is no need for on-site storage of waste products.

What are the benefits of in-line waste recycling?

- Manufacturing waste is eliminated

- Reduced carbon footprint of transport

- No waste sent to landfill

- No on-site storage of waste products.

Plastics that are easily recycled

Our customers can also see our commitment to recycling in our use of easily recoverable and recyclable plastics. We also include post consumer recycled plastics in new products where possible.

Innovative designs reduce material use

Nifco has decades of experience in material and design innovation. This enables us to provide our customers with products like our SRGT range of side-release buckles, The BBU25 (above) combines lightness with a sleek urban style.

Nifco are innovating to supply the demand for smaller, lighter, more reliable buckles and fasteners. Customers enjoy the ease of use and appealing designs of our high performance fasteners, which require less material to manufacture than standard fasteners.

Many of our ultralight recycled cord stoppers weigh less than one gramme, adding significantly to sustainable goals without sacrificing performance. Cord locks like the CL433A pictured above are offered in recycled materials and are also game changers in minimizing material use.

Nifco best fit solutions for green plastic fastener manufacturers

Our wide range of best practice solutions for environmental responsibility help you meet future legislation and regulation aimed at fighting climate change. Nifco green manufacturing increases customer confidence in brand sustainability,

We apply our long experience of innovation to blend function, design,and appearance into the best fit possible for our customers. Contact us to discover how our future-proofed high performance buckles and fastening solutions can help you contribute to meeting the challenge of climate change.