Over generations, headwear closures have evolved through many forms. The functional requirements are the same, but designs have emerged to meet the challenges of emerging consumer preferences and to improve comfort and aesthetic appeal. Nifco’s revolutionary GN Series bring you closures evolved to a new future of security and sophistication.

Table of Contents

What are the different types of headwear closure?

Buckles and fasteners developed for headwear closures are often similar to fasteners used for other apparel, since they share the same functional requirements. This has ranged from simple toggles to fasten under the chin to elasticated bands stitched into the cap and contemporary buckle and velcro solutions.

- Metal buckle

- Plastic buckle

- Hook & Eye

- Velcro

- Elastic

- Bungee toggles

Headwear closures are very difficult to get right. This is because the rounded shape of the head makes it difficult to design a comfortable closure system that is also secure enough to not distract the wearer when doing sports or outdoor activities in windy conditions. This seems like a no-win situation, as increasing the tension reduces comfort, especially when using buckles. Nifco has found a solution, however, that meets all requirements.

How do you make well fitting headwear?

It used to be the case that if you wanted a hat, you had to get one in your size, and for many types of headwear this is still true today. The growing adoption of caps in one-size-fits-all drove a need for closures that could easily be adjusted for length and securely fastened. Well fitting headwear came to depend on the quality of closures and fasteners for comfort and style.

What are 8 essential features of well designed headwear closures?

- Easy to fasten

- Comfortable to wear

- Easy to adjust

- Secure for sports

- Secure in windy weather

- Aesthetically appealing

- Durable

- Environmentally friendly

The problem of making a secure closure that was comfortable to wear, durable, and attractive became apparent from the beginning. Simple metal buckle fasteners are heavy, can dig into the wearer’s head if fastened tightly, and tend to corrode when washed and leave marks on the fabric. They also take a bit of time to adjust securely.

Plastic clip fasteners are an alternative to metal buckles, and meet a couple of these issues by reducing weight and eliminating corrosion, but they can still be uncomfortable if tight fastening is required, if worn for active sports, for example, or in windy conditions.

Can we eliminate buckles from headwear closures?

Hook and loop Velcro-style fasteners seemed to be an excellent way to meet the need for comfort and reduced weight by getting rid of buckles, but they lose their strength over time. This is because they stick to everything and anything and the fastening surface becomes clogged with fluff, which also isn’t a very attractive look.

Designers started working on plastic strip fasteners that used a pop-fit to hold them together, giving a lightweight, secure and comfortable fit but without the corrosion problems of metal or aesthetic penalty of hook and loop. This started a new generation of plastic strip fasteners with shallow pegs that latched into round holes.

How do you make plastic fasteners work for headwear closures?

Plastic has its own engineering challenges, and it turned out that the pegs and holes of plastic strip fasteners tended to stretch and pull open when fastened tightly. This made this new type of fastener not suitable when a really tight fit was needed, especially for sports and outdoor activities.

Nifco engineers applied our long experience in buckle, fastener, and materials technology to this difficult problem and came up with a perfect solution. Combining the lightweight of fabric hook and loop fasteners with the security of buckles in a flat, comfortable strap that stays fastened even in the most challenging conditions.

How did we evolve our revolutionary headwear closure?

We looked at the current requirements of today’s customer for a lightweight, comfortable, secure and aesthetically pleasing fastening system, and rather than attempting to duplicate existing ideas, we considered alternative fastening technologies that we had found highly effective in other applications.

The breakthrough moment came when we considered the effectiveness of cable ties as a fastening technology. Our goal was to reproduce the security of the cable tie, but in an easy to close and open format, and one which would stay just as secure under tension, making it ideal for modern sports and outdoor pursuits.

The GN Series headwear closure from Nifco

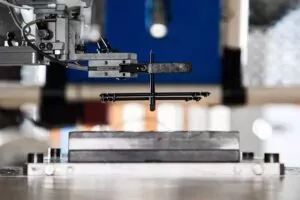

The answer is our GN Series of TPU closures, with flexible teeth that lock into slots on the mating surface for an ultra secure fit, and still easy to adjust even under tension. The carefully designed, engineered, and rigorously tested locking pattern of this new product from Nifco is one of our many innovative patents for unique fastener solutions.

Manufactured from TPU, which is strong and lightweight but soft to the touch, the Nifco GN 201A shown above achieves the highest levels of comfort and weight reduction while maintaining confidence in a secure fit that will not come loose and distract from enjoying sports or other outdoor active pursuits.

Nifco: the best fit for people and planet

Nifco continues to offer the best fit for people and planet with our constant innovation of functional, comfortable and stylish headwear closures made of recycled and recyclable materials. Contact us to discuss how we can enhance your headwear brand with an attractive, innovative solution that your customers will love.